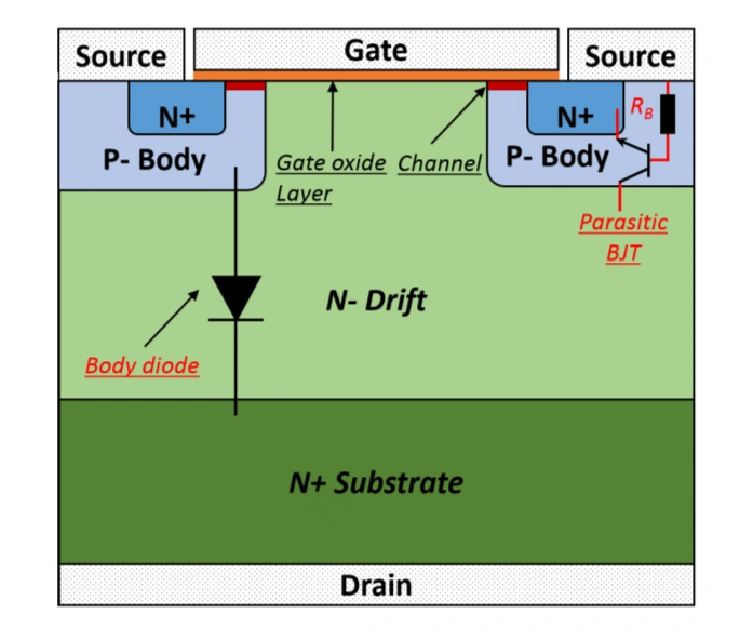

Power MOSFETs are crucial components in modern power electronics, designed to handle high voltages and currents. Let’s explore their unique structural features that enable efficient power handling capabilities.

Basic Structure Overview

Source Metal

║

╔═══╩═══╗

║ n+ ║ n+ ║ Source

════╝ ╚════

p+ p Body

│

│ n- Drift Region

│

│

════════════════ n+ Substrate

║

╨ Drain Metal

Cross-sectional view of a typical Power MOSFET

Vertical Structure

Unlike regular MOSFETs, power MOSFETs employ a vertical structure where current flows from top (source) to bottom (drain), maximizing current handling capacity.

Drift Region

Contains a lightly doped n- region that supports high blocking voltage and manages electric field distribution.

Key Structural Components

- Source Metal: Top metal layer for current collection and distribution

- n+ Source Regions: Heavily doped regions for carrier injection

- p-Body Region: Creates the channel for current flow

- n- Drift Region: Supports voltage blocking capability

- n+ Substrate: Provides low resistance path to drain

- Drain Metal: Bottom metal contact for current flow

Design Consideration

The cell pitch and junction depth are critical parameters that affect the device’s performance characteristics including on-resistance and switching speed.

Cell Structure Details

Key Dimensional Parameters

- Cell Pitch: Typically 2-10 μm

- Gate Oxide Thickness: 50-100 nm

- Junction Depth: 1-3 μm

- Drift Region Thickness: 5-50 μm (voltage dependent)

Structural Layer Analysis

Gate Structure

┌──────────────┐

│ Gate Oxide │

════╝ SiO2 ╚════

- Polysilicon material for gate electrode

- Optimized gate oxide thickness for reliability

- Specialized gate geometry for uniform field distribution

- Multiple parallel cells for current handling

Channel Formation

Gate

║

S ▼ S

═╗ ═══ ╔═

║ Chr ║ ← Inversion

n+╚═══╝n+ Channel

p-body Formation

│

│ n-

│

Channel formation under gate bias

Advanced Structural Features

Trench Structure

S G S

┌─╨─┐

│ │

n+ ═╣ ╠═ n+

│ │

│ │

p │ │ p

│ │

└───┘

n-

Modern trench design for reduced on-resistance

Planar Structure

S G S

╨ ╨ ╨

═══╗ ╔═══

n+ ═╝ ╚═ n+

p p

n-

Traditional planar design with proven reliability

Design Evolution

Modern power MOSFETs often incorporate advanced features like:

- Super-junction structures

- Charge-balanced columns

- Shield electrodes

- Advanced termination structures

Current Flow Path

Current Flow Direction

Source

↓ ↓ ↓

═══════

n+ ║ ║ n+

║ → ║

p ║ ↓ ║ p

║ ↓ ║

║ ↓ ║

n-

║ ↓ ║

↓ ↓ ↓

Drain

Vertical current flow pattern in power MOSFET

Edge Termination Structure

Active Area │ Termination Region

│

═══════════│════════════════

Active │ Guard Rings

Cells │ ┌─┐ ┌─┐

═══════════│════╧═╧═╧═╧════

│

n- │ Field Plate

│

═══════════│════════════════

Edge termination design for voltage blocking

Termination Features

- Field rings for electric field distribution

- Field plates for enhanced blocking voltage

- Junction termination extension (JTE)

- Floating guard rings

Device Parameters and Dimensions

Critical Dimensions

| Parameter | Typical Range |

|---|---|

| Channel Length | 0.5 – 2 μm |

| Cell Pitch | 2 – 10 μm |

| Drift Region | 5 – 50 μm |

| Gate Oxide | 50 – 100 nm |

Manufacturing Considerations

- Precise control of doping profiles

- Optimized thermal budget management

- Critical alignment requirements

- Surface passivation quality