The Evolution of E-MOSFET Technology

The journey of E-MOSFET technology spans several decades, marking significant milestones in semiconductor innovation. Since its inception in the 1960s, E-MOSFETs have revolutionized electronic circuit design, offering unprecedented advantages in power efficiency, switching speed, and integration density. Today, these devices form the backbone of digital electronics, power management systems, and countless other applications.

The journey of E-MOSFET technology spans several decades, marking significant milestones in semiconductor innovation. Since its inception in the 1960s, E-MOSFETs have revolutionized electronic circuit design, offering unprecedented advantages in power efficiency, switching speed, and integration density. Today, these devices form the backbone of digital electronics, power management systems, and countless other applications.

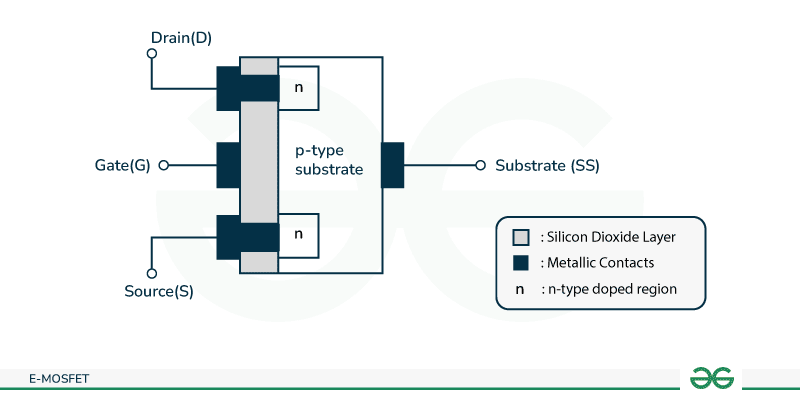

E-MOSFET Construction: A Detailed Analysis

Basic Structure and Components

The E-MOSFET’s construction involves several precisely engineered layers and regions:

Substrate

P-type or N-type semiconductor material forming the foundation

Source and Drain

Heavily doped regions with opposite polarity to the substrate

Gate Oxide

Thin insulating layer of silicon dioxide

Gate Terminal

Typically made of heavily doped polysilicon or metal

Manufacturing Process

The fabrication of E-MOSFETs involves sophisticated manufacturing processes, including:

- Substrate preparation and cleaning

- Gate oxide growth through thermal oxidation

- Polysilicon deposition and patterning

- Ion implantation for source and drain regions

- Metallization and contact formation

- Passivation and final testing

| Layer | Material | Typical Thickness | Function |

|---|---|---|---|

| Gate Oxide | SiO2 | 2-100 nm | Insulation and field effect control |

| Gate Terminal | Polysilicon/Metal | 200-400 nm | Control electrode |

| Source/Drain | Doped Silicon | 0.5-2 µm | Current flow terminals |

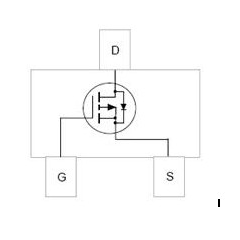

Working Principle of E-MOSFET

Channel Formation and Operation Modes

The E-MOSFET’s operation relies on the creation of a conductive channel between source and drain terminals. This process involves several distinct stages:

The E-MOSFET’s operation relies on the creation of a conductive channel between source and drain terminals. This process involves several distinct stages:

Key Operating Principles:

- When gate voltage is below threshold (VGS < Vth):

- No conductive channel exists

- Device remains in cut-off mode

- Negligible drain current flows

- When gate voltage exceeds threshold (VGS > Vth):

- Inversion layer forms beneath the gate oxide

- Conductive channel establishes between source and drain

- Current flow becomes possible

Operating Regions

| Region | Condition | Characteristics |

|---|---|---|

| Cut-off | VGS < Vth | Device OFF, minimal leakage current |

| Linear/Triode | VGS > Vth, VDS < (VGS – Vth) | Channel acts as resistor, ID proportional to VDS |

| Saturation | VGS > Vth, VDS > (VGS – Vth) | Current nearly constant with VDS |

Applications and Performance Parameters

Power Management

Voltage regulators, DC-DC converters, and power supplies

Digital Logic

Microprocessors, memory devices, and logic gates

Motor Control

Variable frequency drives and motor speed controllers

Audio Amplification

High-fidelity audio equipment and speakers

Critical Performance Parameters

When selecting an E-MOSFET for your application, consider these essential parameters:

| Parameter | Symbol | Typical Range | Impact |

|---|---|---|---|

| Threshold Voltage | Vth | 0.5V – 4V | Determines switching point |

| On-Resistance | RDS(on) | 1mΩ – 100mΩ | Affects power efficiency |

| Gate Charge | Qg | 1nC – 100nC | Switching speed capability |

| Maximum Drain Current | ID(max) | 1A – 100A+ | Current handling capacity |

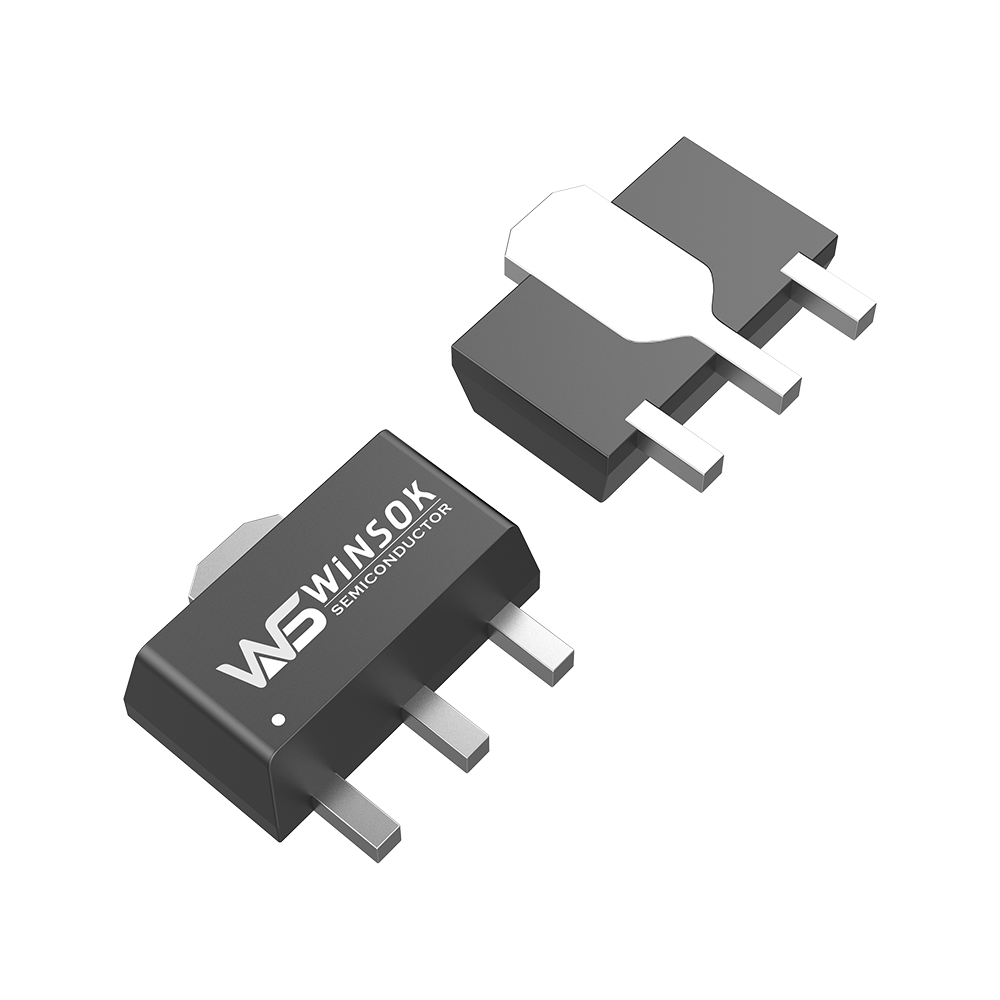

Why Choose Winsok E-MOSFETs from Olukey?

Winsok, a leading Taiwan-based MOSFET manufacturer, combines cutting-edge technology with rigorous quality control. Through Olukey, their authorized distributor, you gain access to:

- Industry-leading performance specifications

- Comprehensive technical support

- Reliable supply chain management

- Competitive pricing structures

- Quick delivery timeframes

Ready to Enhance Your Electronic Designs?

Our team of experts is ready to help you select the perfect E-MOSFET for your application. Contact us today for detailed specifications, samples, or volume pricing.

Performance Guarantee

Every Winsok E-MOSFET supplied through Olukey undergoes stringent quality testing and comes with:

Every Winsok E-MOSFET supplied through Olukey undergoes stringent quality testing and comes with:

- 100% functionality testing

- Comprehensive datasheet documentation

- Authentication certificates

- Extended warranty coverage

- RoHS and environmental compliance

Looking for specific E-MOSFET parameters or custom solutions? Our engineering team can help you identify the optimal device for your requirements.