When the MOSFET is connected to the bus and load ground, a high voltage side switch is used. Often P-channel MOSFETs are used in this topology, again for voltage drive considerations. Determining the current rating The second step is to select the current rating of the MOSFET. Depending on the circuit structure, this current rating should be the maximum current that the load can withstand under all circumstances.

Similar to the case of voltage, the designer must ensure that the selected MOSFET can withstand this current rating, even when the system is generating spike currents. The two current cases considered are continuous mode and pulse spikes. This parameter is referenced by the FDN304P DATASHEET, where the MOSFET is in steady state in continuous conduction mode, when current is continuously flowing through the device.

Pulse spikes are when there is a large surge (or spike) of current flowing through the device. Once the maximum current under these conditions has been determined, it is simply a matter of directly selecting a device that can withstand this maximum current.

After selecting the rated current, the conduction loss must also be calculated. In practice, MOSFETs are not ideal devices because there is a loss of power during the conductive process, which is called conduction loss.

The MOSFET acts as a variable resistor when it is "on", as determined by the RDS(ON) of the device, and varies significantly with temperature. The power dissipation of the device can be calculated from Iload2 x RDS(ON), and since the on-resistance varies with temperature, the power dissipation varies proportionally. The higher the voltage VGS applied to the MOSFET, the smaller the RDS(ON) will be; conversely the higher the RDS(ON) will be. For the system designer, this is where the tradeoffs come into play depending on the system voltage. For portable designs, it is easier (and more common) to use lower voltages, while for industrial designs, higher voltages can be used.

Note that the RDS(ON) resistance rises slightly with current. Variations on the various electrical parameters of the RDS(ON) resistor can be found in the technical data sheet provided by the manufacturer.

Determining Thermal Requirements The next step in selecting a MOSFET is to calculate the thermal requirements of the system. The designer must consider two different scenarios, the worst case and the true case. It is recommended that the calculation for the worst-case scenario be used, as this result provides a greater margin of safety and ensures that the system will not fail.

There are also some measurements to be aware of on the MOSFET datasheet; such as the thermal resistance between the semiconductor junction of the packaged device and the ambient environment, and the maximum junction temperature. The junction temperature of the device is equal to the maximum ambient temperature plus the product of thermal resistance and power dissipation (junction temperature = maximum ambient temperature + [thermal resistance x power dissipation]). From this equation the maximum power dissipation of the system can be solved, which is by definition equal to I2 x RDS(ON).

Since the designer has determined the maximum current that will pass through the device, RDS(ON) can be calculated for different temperatures. It is important to note that when dealing with simple thermal models, the designer must also consider the heat capacity of the semiconductor junction/device enclosure and the enclosure/environment; i.e., it is required that the printed circuit board and the package do not warm up immediately.

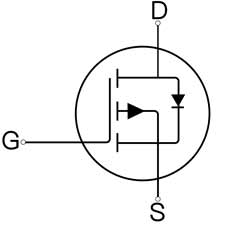

Usually, a PMOSFET, there will be a parasitic diode present, the diode's function is to prevent the source-drain reverse connection, for PMOS, the advantage over NMOS is that its turn-on voltage can be 0, and the voltage difference between the DS voltage is not much, while the NMOS on condition requires that the VGS be greater than the threshold, which will lead to the control voltage is inevitably greater than the required voltage, and there will be unnecessary trouble. PMOS is selected as the control switch, there are the following two applications: the first application, the PMOS to carry out the voltage selection, when V8V exists, then the voltage is all provided by V8V, the PMOS will be turned off, the VBAT does not provide voltage to the VSIN, and when the V8V is low, the VSIN is powered by 8V. Note the grounding of R120, a resistor that steadily pulls the gate voltage down to ensure proper PMOS turn-on, a state hazard associated with the high gate impedance described earlier.

The functions of D9 and D10 are to prevent voltage back-up, and D9 can be omitted. It should be noted that the DS of the circuit is actually reversed, so that the function of the switching tube cannot be achieved by the conduction of the attached diode, which should be noted in practical applications. In this circuit, the control signal PGC controls whether V4.2 supplies power to P_GPRS. This circuit, the source and drain terminals are not connected to the opposite, R110 and R113 exist in the sense that R110 control gate current is not too large, R113 control gate normality, R113 pull-up for high, as of PMOS, but also can be seen as a pull-up on the control signal, when the MCU internal pins and pull-up, that is, the output of the open-drain when the output does not drive the PMOS off, at this time, the It will need an external voltage to give the pull-up, so resistor R113 plays two roles. r110 can be smaller, to 100 ohms can be.

Small package MOSFETs have a unique role to play.