Fundamentals of Avalanche Behavior

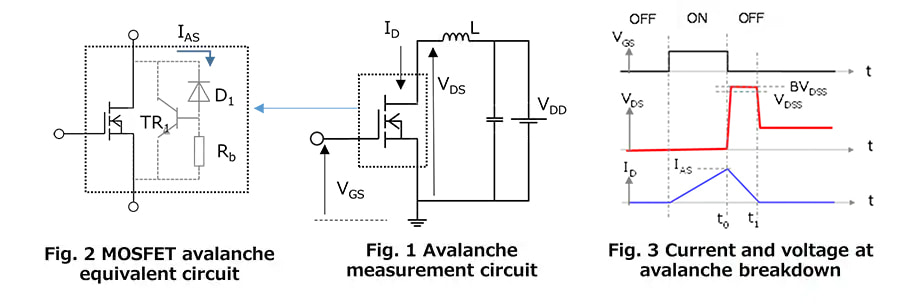

Avalanche breakdown occurs when the voltage across a MOSFET’s drain-source junction exceeds its rated breakdown voltage (VBRDSS). During this phenomenon, the device must safely dissipate the stored energy without suffering permanent damage.

Avalanche breakdown occurs when the voltage across a MOSFET’s drain-source junction exceeds its rated breakdown voltage (VBRDSS). During this phenomenon, the device must safely dissipate the stored energy without suffering permanent damage.

| Parameter | Symbol | Description | Critical Factors |

|---|---|---|---|

| Avalanche Energy | EAS | Maximum energy absorbable during avalanche | Temperature, current density |

| Avalanche Current | IAS | Maximum current during avalanche event | Pulse width, duty cycle |

| Breakdown Voltage | VBRDSS | Voltage at which avalanche occurs | Temperature coefficient, design margin |

Critical Design Considerations

Temperature Effects on Avalanche Operation

Temperature significantly impacts a MOSFET’s avalanche capability. As junction temperature increases, both the breakdown voltage and avalanche energy handling capability typically decrease.

Design Guidelines for Avalanche-Rated Applications

- Always calculate the maximum possible avalanche energy in your application

- Include a safety margin of at least 30% for avalanche energy ratings

- Consider the impact of parasitic inductances in your PCB layout

- Implement proper thermal management solutions

- Use snubber circuits when necessary to limit voltage spikes

Winsok’s Advanced Avalanche-Rated MOSFETs

Winsok’s latest generation of power MOSFETs features enhanced avalanche capability through advanced cell design and optimized silicon processing. These devices offer:

- Superior avalanche energy handling capacity

- Excellent thermal performance

- Consistent breakdown voltage across temperature

- Comprehensive datasheet specifications for avalanche parameters

Avalanche Testing Methodologies

Proper avalanche testing is essential for validating MOSFET reliability in demanding applications. Here’s a comprehensive overview of industry-standard testing approaches and best practices.

Proper avalanche testing is essential for validating MOSFET reliability in demanding applications. Here’s a comprehensive overview of industry-standard testing approaches and best practices.

Unclamped Inductive Switching (UIS) Test

The UIS test is the primary method for evaluating a MOSFET’s avalanche capability. This test simulates worst-case avalanche conditions by forcing the device into avalanche mode using an inductor to store energy.

| Test Parameter | Typical Range | Considerations |

|---|---|---|

| Test Current (IAS) | 1A – 100A | Device rating dependent |

| Inductance (L) | 100µH – 1mH | Energy storage calculation critical |

| Pulse Width | 50µs – 500µs | Temperature rise consideration |

| Case Temperature | 25°C – 150°C | Multiple temperature points needed |

Test Setup Requirements

- High-precision current measurement capability

- Fast voltage probes with adequate bandwidth

- Temperature-controlled test fixture

- Accurate timing control for pulse generation

- Protection circuits for equipment safety

Data Analysis and Interpretation

Key Parameters to Monitor

During avalanche testing, several critical parameters must be carefully monitored and analyzed:

- Peak avalanche current and duration

- Voltage waveform characteristics

- Temperature rise during avalanche

- Recovery characteristics post-avalanche

- Device degradation indicators

Failure Analysis Techniques

| Failure Mode | Indicators | Preventive Measures |

|---|---|---|

| Thermal Runaway | Sudden current spike, device shorting | Proper thermal design, current limiting |

| Gate Oxide Breakdown | Increased leakage current, gate failure | Gate voltage control, proper driving |

| Hot Carrier Degradation | Gradual Vth shift, increased RDS(on) | Operating within safe area |

Expert Testing Support from Olukey

As Winsok’s authorized distributor, Olukey provides comprehensive testing support and validation services:

- Advanced testing facilities with state-of-the-art equipment

- Expert analysis of test results and recommendations

- Custom testing solutions for specific applications

- Detailed reporting and documentation

Practical Implementation Guidelines

Design Verification Checklist

Before finalizing your design, ensure these critical aspects are addressed:

- Calculate maximum possible avalanche energy in the application

- Verify temperature rise under worst-case conditions

- Implement appropriate derating factors

- Consider environmental factors affecting performance

- Plan for regular maintenance and monitoring

For detailed specifications and availability of Winsok’s avalanche-rated MOSFETs, contact Olukey’s technical support team. Our engineers can help you select the optimal device for your application and provide comprehensive design support.