MOSFETs are widely used in analog and digital circuits and are closely related to our lives.The advantages of MOSFETs are: the drive circuit is relatively simple.MOSFETs require much less drive current than BJTs, and can usually be driven directly by CMOS or open collector TTL driver circuits. Second, MOSFETs switch faster and can operate at higher speeds because there is no charge storage effect. In addition, MOSFETs do not have a secondary breakdown failure mechanism. The higher the temperature, often the stronger the endurance, the lower the possibility of thermal breakdown, but also in a wider temperature range to provide better performance.MOSFETs have been used in a large number of applications, in consumer electronics, industrial products, electromechanical equipment, smart phones and other portable digital electronic products can be found everywhere.

MOSFET application case analysis

1、Switching power supply applications

By definition, this application requires MOSFETs to conduct and shut down periodically. At the same time, there are dozens of topologies can be used for switching power supply, such as DC-DC power supply commonly used in the basic buck converter relies on two MOSFETs to perform the switching function, these switches alternately in the inductor to store energy, and then open the energy to the load. Currently, designers often choose frequencies in the hundreds of kHz and even above 1MHz, due to the fact that the higher the frequency, the smaller and lighter the magnetic components. The second most important MOSFET parameters in switching power supplies include output capacitance, threshold voltage, gate impedance and avalanche energy.

2, motor control applications

Motor control applications are another application area for power MOSFETs. Typical half-bridge control circuits use two MOSFETs (full-bridge uses four), but the two MOSFETs off time (dead time) is equal. For this application, the reverse recovery time (trr) is very important. When controlling an inductive load (such as a motor winding), the control circuit switches the MOSFET in the bridge circuit to the off state, at which point another switch in the bridge circuit temporarily reverses the current through the body diode in the MOSFET. Thus, the current circulates again and continues to power the motor. When the first MOSFET conducts again, the charge stored in the other MOSFET diode must be removed and discharged through the first MOSFET. This is an energy loss, so the shorter the trr, the smaller the loss.

3, automotive applications

The use of power MOSFETs in automotive applications has grown rapidly over the past 20 years. Power MOSFET is selected because it can withstand transient high-voltage phenomena caused by the common automotive electronic systems, such as load shedding and sudden changes in system energy, and its package is simple, mainly using TO220 and TO247 packages. At the same time, applications such as power windows, fuel injection, intermittent wipers, and cruise control are gradually becoming standard in most automobiles, and similar power devices are required in the design. During this period, automotive power MOSFETs evolved as motors, solenoids, and fuel injectors became more popular.

MOSFETs used in automotive devices cover a wide range of voltages, currents, and on-resistance. Motor control devices bridge configurations using 30V and 40V breakdown voltage models, 60V devices are used to drive loads where sudden load unloading and surge starting conditions must be controlled, and 75V technology is required when the industry standard is shifted to 42V battery systems. High auxiliary voltage devices require the use of 100V to 150V models, and MOSFET devices above 400V are used in engine driver units and control circuits for high intensity discharge (HID) headlamps.

Automotive MOSFET drive currents range from 2A to over 100A, with on-resistance ranging from 2mΩ to 100mΩ. MOSFET loads include motors, valves, lamps, heating components, capacitive piezoelectric assemblies and DC/DC power supplies. Switching frequencies typically range from 10kHz to 100kHz, with the caveat that motor control is not suitable for switching frequencies above 20kHz. Other major requirements are UIS performance, operating conditions at the junction temperature limit (-40 degrees to 175 degrees, sometimes up to 200 degrees) and high reliability beyond the life of the car.

4, LED lamps and lanterns driver

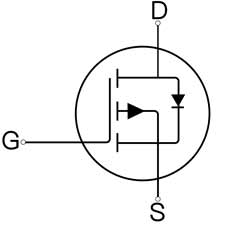

In the design of LED lamps and lanterns often use MOSFET, for LED constant current driver, generally use NMOS. power MOSFET and bipolar transistor is usually different. Its gate capacitance is relatively large. The capacitor needs to be charged before conduction. When the capacitor voltage exceeds the threshold voltage, the MOSFET begins to conduct. Therefore, it is important to note during design that the load capacity of the gate driver needs to be large enough to ensure that the charging of the equivalent gate capacitance (CEI) is completed within the time required by the system.

The switching speed of the MOSFET is highly dependent on the charging and discharging of the input capacitance. Although the user can not reduce the value of Cin, but can reduce the value of the gate drive loop signal source internal resistance Rs, thus reducing the gate loop charging and discharging time constants, to speed up the switching speed, the general IC drive capability is mainly reflected here, we say that the choice of MOSFET refers to the external MOSFET drive constant-current ICs. built-in MOSFET ICs do not need to be considered. Generally speaking, the external MOSFET will be considered for currents exceeding 1A. In order to obtain a larger and more flexible LED power capability, the external MOSFET is the only way to choose the IC needs to be driven by the appropriate capability, and the MOSFET input capacitance is the key parameter.