Lithium as a new type of environmentally friendly batteries, has long been gradually used in battery cars. Unknown because of the characteristics of lithium iron phosphate rechargeable batteries, in use must be its battery charging process to carry out maintenance to prevent overcharging loss of power or over-temperature to ensure that the rechargeable battery safety work. However, overcurrent protection is a polarization of the whole process of charging and discharging extreme work standards, so how to choose the power MOSFET model specifications and design programs suitable for the drive circuit?

Specific work, based on different applications, will apply several power MOSFETs working in parallel to reduce the on-resistor and improve the thermal conductivity characteristics. All normal operation, manipulate the data signal to manipulate the MOSFET on, lithium battery pack terminals P and P- output voltage for operational applications. At this time, the power MOSFET has been in the conduction situation, the power loss is only conduction loss, no power switching loss, the total power loss of the power MOSFET is not high, the temperature rise is small, so the power MOSFET can work safely.

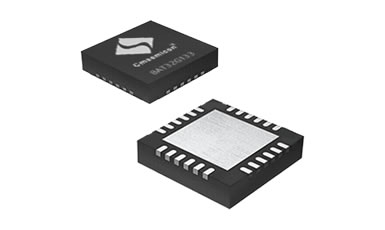

However, when the load generates a short-circuit fault, the short-circuit capacity suddenly increases from several tens of amperes for normal operation to several hundreds of amperes because the circuit resistance is not large and the rechargeable battery has a strong charging capacity, and the power MOSFETs are very easy to be destroyed in such a case. Therefore, if possible, select a MOSFET with a small RDS (ON), so that fewer MOSFETs can be used in parallel. Several MOSFETs in parallel are susceptible to current imbalance. Separate and identical push resistors are required for parallel MOSFETs to avoid fluctuations between MOSFETs.