Selecting the right MOSFET involves considering multiple parameters to ensure it meets the requirements of a specific application. Here are the key steps and considerations for choosing a MOSFET:

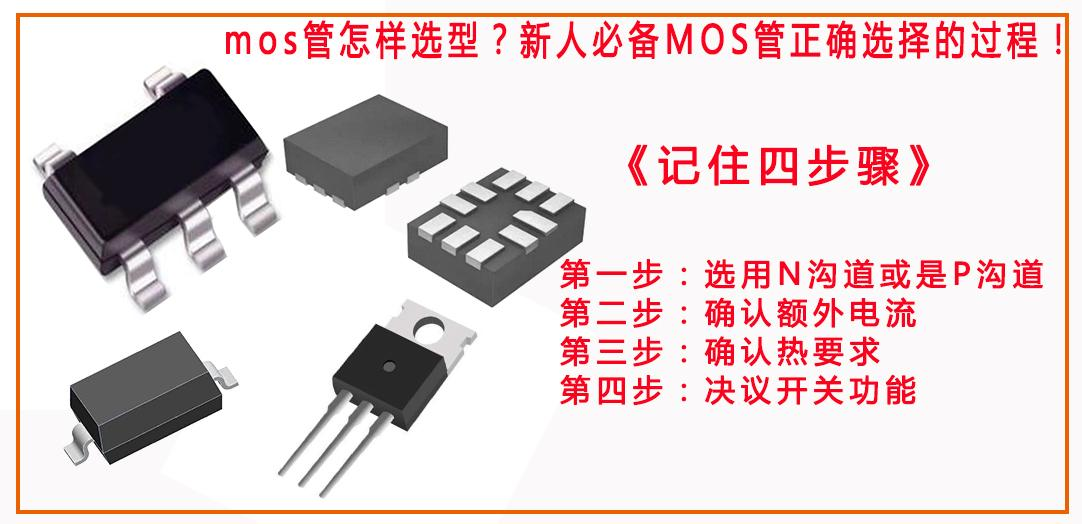

1. Determine the Type

- N-channel or P-channel: Choose between an N-channel or P-channel MOSFET based on the circuit design. Typically, N-channel MOSFETs are used for low-side switching, while P-channel MOSFETs are used for high-side switching.

2. Voltage Ratings

- Maximum Drain-Source Voltage (VDS): Determine the maximum drain-to-source voltage. This value should exceed the actual voltage stress in the circuit with enough margin for safety.

- Maximum Gate-Source Voltage (VGS): Ensure the MOSFET meets the voltage requirements of the driving circuit and does not exceed the gate-source voltage limit.

3. Current Capability

- Rated Current (ID): Select a MOSFET with a rated current that is greater than or equal to the maximum expected current in the circuit. Consider pulse peak current to ensure the MOSFET can handle maximum current under these conditions.

4. On-Resistance (RDS(on))

- On-Resistance: The on-resistance is the resistance of the MOSFET when it is conducting. Choosing a MOSFET with a low RDS(on) reduces power loss and improves efficiency.

5. Switching Performance

- Switching Speed: Consider the switching frequency (FS) and the rise/fall times of the MOSFET. For high-frequency applications, select a MOSFET with fast switching characteristics.

- Capacitance: The gate-drain, gate-source, and drain-source capacitances affect switching speed and efficiency, so these should be considered during selection.

6. Package and Thermal Management

- Package Type: Choose an appropriate package type based on PCB space, thermal requirements, and manufacturing process. The size and thermal performance of the package will influence the mounting and cooling efficiency of the MOSFET.

- Thermal Requirements: Analyze the system's thermal needs, especially under worst-case conditions. Choose a MOSFET that can operate normally under these conditions to avoid system failure due to overheating.

7. Temperature Range

- Ensure the operating temperature range of the MOSFET matches the environmental requirements of the system.

8. Special Application Considerations

- Low-Voltage Applications: For applications using 5V or 3V power supplies, pay close attention to the MOSFET's gate voltage limits.

- Wide Voltage Applications: A MOSFET with a built-in Zener diode might be required to limit the gate voltage swing.

- Dual Voltage Applications: Special circuit designs may be needed to control the high-side MOSFET effectively from the low-side.

9. Reliability and Quality

- Consider the manufacturer's reputation, quality assurance, and long-term stability of the component. For high-reliability applications, automotive-grade or other certified MOSFETs may be required.

10. Cost and Availability

- Consider the cost of the MOSFET and the supplier's lead times and supply stability, ensuring the component meets both performance and budgetary requirements.

Summary of Selection Steps:

- Determine whether an N-channel or P-channel MOSFET is needed.

- Establish the maximum drain-source voltage (VDS) and gate-source voltage (VGS).

- Choose a MOSFET with a rated current (ID) that can handle peak currents.

- Select a MOSFET with low RDS(on) for improved efficiency.

- Consider the MOSFET's switching speed and the effect of capacitance on performance.

- Choose an appropriate package type based on space, thermal needs, and PCB design.

- Ensure the operating temperature range fits the system's requirements.

- Account for special needs, such as voltage limitations and circuit design.

- Evaluate the manufacturer's reliability and quality.

- Factor in cost and supply chain stability.

When selecting a MOSFET, it is recommended to consult the device's datasheet and conduct detailed circuit analysis and calculations to ensure it meets all design conditions. Performing simulations and tests is also a critical step to verify the correctness of your selection.