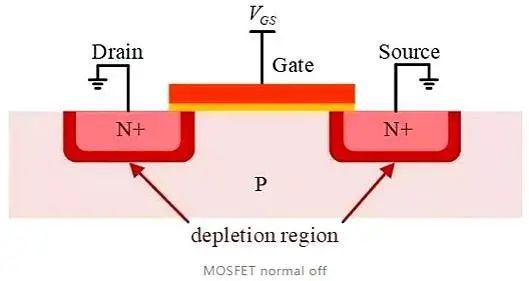

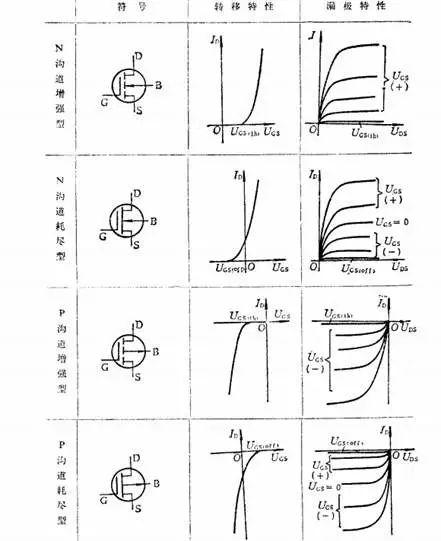

The two main causes of MOSFET failure:

Voltage failure: that is, the BVdss voltage between the drain and source exceeds the rated voltage of the MOSFET and reaches a certain capacity, causing the MOSFET to fail.

Gate Voltage Failure: The gate suffers an abnormal voltage spike, resulting in a gate oxygen layer failure.

Collapse fault (voltage failure)

What exactly is avalanche damage? Simply put, a MOSFET is a failure mode created by the superposition between bus voltages, transformer reflection voltages, leakage spike voltages, etc. and the MOSFET. In short, it is a common failure that occurs when the voltage at the drain-source pole of a MOSFET exceeds its specified voltage value and reaches a certain energy limit.

Measures to prevent avalanche damage:

-Reduce the dosage appropriately. In this industry, it is usually reduced by 80-95%. Choose based on the company's warranty terms and line priorities.

-Reflective voltage is reasonable.

-RCD, TVS absorption circuit design is reasonable.

-High current wiring should be as large as possible to minimize parasitic inductance.

-Select the appropriate gate resistor Rg.

-Add RC damping or Zener diode absorption for high power supplies as needed.

Gate Voltage Failure

There are three main causes of abnormally high grid voltages: static electricity during production, transportation and assembly; high voltage resonance generated by parasitic parameters of equipment and circuits during power system operation; and transmission of high voltage through the Ggd to the grid during high voltage shocks (a fault that is more common during lightning strike testing).

Measures to prevent gate voltage faults:

Overvoltage protection between gate and source: When the impedance between gate and source is too high, the sudden change in voltage between gate and source is coupled to the gate through the capacitance between the electrodes, resulting in a very high UGS voltage over-regulation, leading to over-regulation of the gate. Permanent oxidative damage. If the UGS is at a positive transient voltage, the device may also cause errors. On this basis, the impedance of the gate drive circuit should be appropriately reduced and a damping resistor or 20V stabilizing voltage should be connected between the gate and the source. Particular care should be taken to prevent open door operation.

Overvoltage protection between discharge tubes: If there is an inductor in the circuit, sudden changes in leakage current (di/dt) when the unit is turned off will result in leakage voltage overshoots well above the supply voltage, causing damage to the unit. Protection should include a Zener clamp, RC clamp, or RC suppression circuit.