Understanding MOSFET Power Breakdown

Power breakdown in MOSFETs is a critical parameter that determines device reliability and performance limits. Proper measurement techniques are essential for accurate characterization and preventing device failure during testing.

Power breakdown in MOSFETs is a critical parameter that determines device reliability and performance limits. Proper measurement techniques are essential for accurate characterization and preventing device failure during testing.

Key Parameters to Measure

| Parameter | Description | Typical Test Conditions |

|---|---|---|

| Breakdown Voltage (BVDSS) | Maximum voltage before avalanche | VGS = 0V, ID = specified leakage current |

| Maximum Power Dissipation (PD) | Total power handling capability | TC = 25°C, derated above specified temperature |

| Safe Operating Area (SOA) | Combined voltage/current limits | Various operating points under pulsed conditions |

| Avalanche Energy (EAS) | Single-pulse energy capability | Inductive load switching test |

Required Test Equipment

- High-voltage power supply (rated above expected BVDSS)

- Precision current source/meter

- Oscilloscope with high voltage probes

- Temperature controlled test fixture

- Curve tracer (recommended)

- Protection circuits and safety equipment

Winsok Quality Assurance

All Winsok MOSFETs distributed by Olukey undergo rigorous testing procedures using state-of-the-art equipment to ensure:

- Accurate breakdown voltage specifications

- Verified power handling capabilities

- 100% production testing for critical parameters

- Full traceability and reliability data

Step-by-Step Measurement Procedures

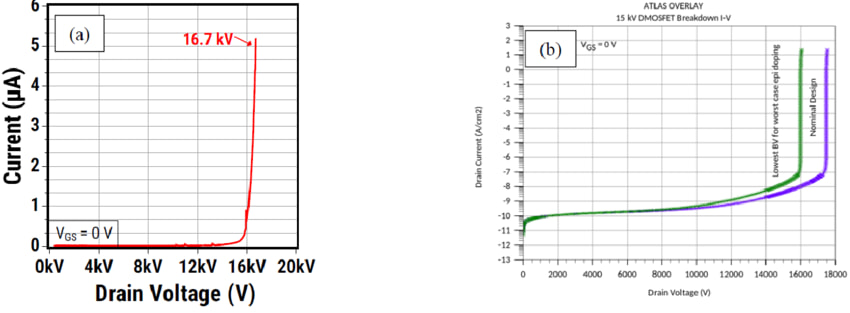

1. Breakdown Voltage Measurement

Follow these steps for safe and accurate BVDSS measurement:

- Configure test setup with current limiting resistance

- Ground the gate terminal (VGS = 0V)

- Gradually increase VDS while monitoring drain current

- Record voltage at specified leakage current level

- Verify temperature effects if required

2. Power Dissipation Testing

| Test Type | Method | Key Considerations |

|---|---|---|

| DC Power Test | Continuous power application | Thermal equilibrium required |

| Pulsed Power Test | Short duration power pulses | Peak power capability verification |

| SOA Testing | Multiple operating points | Temperature monitoring critical |

3. Thermal Measurement Techniques

- Use calibrated thermal imaging equipment

- Monitor junction temperature via TSP method

- Account for thermal resistance of test setup

- Allow sufficient time for thermal stabilization

Advanced Testing Considerations

Safe Operating Area Verification

SOA testing requires careful attention to multiple parameters:

| Region | Limiting Factor | Test Method |

|---|---|---|

| RDS(on) Limited | Maximum current rating | DC test at low VDS |

| Current Limited | Bond wire/die limits | Pulsed testing |

| Power Limited | Thermal dissipation | Thermal equilibrium test |

| Voltage Limited | Breakdown voltage | High voltage sweep |

Avalanche Energy Testing

Critical for applications with inductive loads:

- Setup unclamped inductive switching circuit

- Calculate energy storage in inductor

- Monitor device temperature during testing

- Verify repetitive avalanche capability if required

Common Testing Pitfalls to Avoid

Important considerations for accurate measurements:

- Insufficient current limiting protection

- Improper temperature monitoring

- Inadequate test fixture thermal management

- Missing safety interlocks

- Poor measurement connections

Data Analysis and Reporting

- Record all test conditions and parameters

- Generate standardized test reports

- Compare results with datasheet specifications

- Document any deviations or anomalies

- Maintain calibration records

Laboratory Safety Guidelines

Essential safety measures for high-power testing:

- Use proper personal protective equipment

- Implement emergency shutdown procedures

- Maintain adequate workspace isolation

- Follow high-voltage safety protocols

- Proper handling of failed devices

Professional Testing Services

Olukey offers comprehensive MOSFET testing services featuring:

- State-of-the-art test equipment

- Certified testing procedures

- Detailed test reports and analysis

- Expert technical consultation

- Quick turnaround time

Need Professional MOSFET Testing Support?

Trust Olukey’s expertise in MOSFET testing and characterization. Our partnership with Winsok ensures access to both quality products and professional testing services.

Trust Olukey’s expertise in MOSFET testing and characterization. Our partnership with Winsok ensures access to both quality products and professional testing services.

Whether you need individual device testing or complete characteristic verification, our technical team is ready to support your requirements with professional testing services and expert guidance.