Understanding Optocoupler MOSFET Drivers

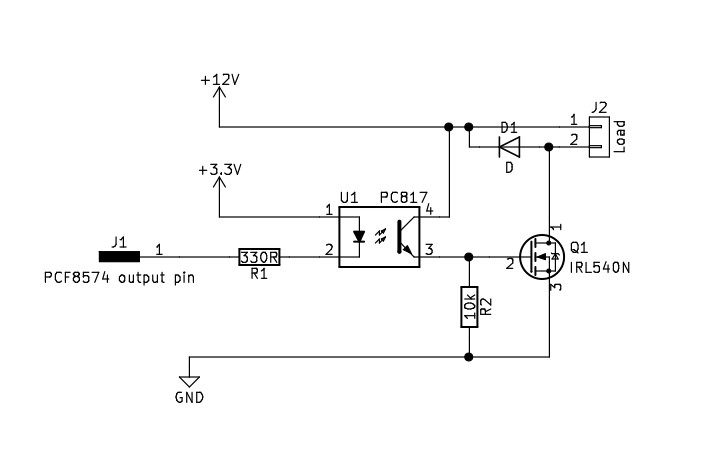

Optocoupler MOSFET driver circuits combine the isolation capabilities of optocouplers with the switching efficiency of MOSFETs, creating a robust solution for power control applications. These circuits are fundamental in modern power electronics, providing essential features such as:

Optocoupler MOSFET driver circuits combine the isolation capabilities of optocouplers with the switching efficiency of MOSFETs, creating a robust solution for power control applications. These circuits are fundamental in modern power electronics, providing essential features such as:

- Galvanic isolation between control and power circuits

- High-speed switching capabilities

- Enhanced noise immunity

- Protection against voltage spikes and transients

- Compatibility with various logic level inputs

Key Components and Their Functions

| Component | Function | Key Considerations |

|---|---|---|

| Optocoupler | Provides electrical isolation | CTR, speed, isolation voltage |

| MOSFET | Power switching element | RDS(on), voltage rating, current capacity |

| Gate Driver | MOSFET control interface | Drive current, propagation delay |

| Protection Components | Circuit protection | Voltage ratings, response time |

Critical Design Considerations for Optocoupler MOSFET Circuits

When designing optocoupler MOSFET driver circuits, several critical factors must be carefully considered to ensure optimal performance and reliability. Here are the key aspects that deserve special attention:

Essential Design Parameters

- Gate charge and discharge timing

- Power supply considerations

- Layout and thermal management

- EMI/EMC compliance

- Protection mechanisms

Common Design Challenges and Solutions

| Challenge | Impact | Solution |

|---|---|---|

| Switching Speed Limitations | Reduced efficiency, increased power loss | Optimize gate drive current, minimize parasitic inductance |

| Gate Ringing | False triggering, EMI issues | Add gate resistor, optimize PCB layout |

| Thermal Management | Component stress, reliability issues | Proper heatsinking, thermal design considerations |

| Ground Bounce | Signal integrity problems | Careful ground planning, separate power/signal grounds |

PCB Layout Best Practices

The PCB layout is crucial for the optimal performance of optocoupler MOSFET driver circuits. Consider these essential guidelines:

- Keep gate drive traces short and wide

- Minimize loop areas in high-current paths

- Use proper isolation spacing

- Implement star-point grounding

- Consider thermal relief for power components

Protection and Safety Features

Implementing proper protection mechanisms is essential for reliable operation:

- Overcurrent protection through current sensing

- Overvoltage protection using TVS diodes

- Temperature monitoring and shutdown

- Isolation barrier integrity monitoring

- Fault detection and reporting mechanisms

Quality Components from Winsok Through Olukey

As the authorized distributor for Winsok, a leading Taiwan-based MOSFET manufacturer, Olukey provides access to high-quality components essential for your optocoupler MOSFET driver circuit designs. Our partnership with Winsok ensures:

- Access to latest-generation MOSFETs with optimal specifications

- Comprehensive technical support and documentation

- Reliable supply chain and competitive pricing

- Quality assurance and warranty support

- Custom solutions for specific applications

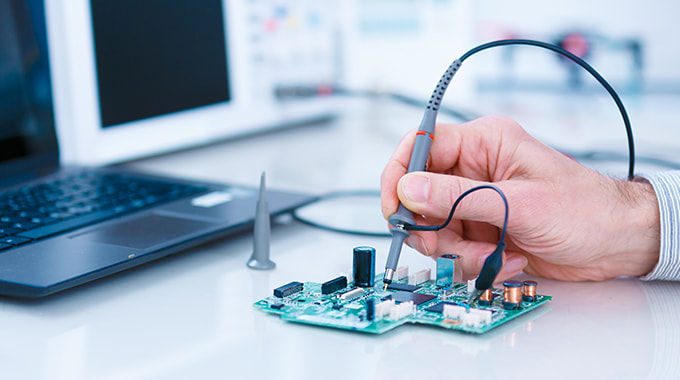

Testing and Validation

Proper testing and validation procedures are crucial for ensuring reliable operation:

Proper testing and validation procedures are crucial for ensuring reliable operation:

| Test Parameter | Test Method | Acceptance Criteria |

|---|---|---|

| Isolation Voltage | Hi-pot testing | >2.5kV for 1 minute |

| Switching Performance | Rise/fall time measurement | |

| Thermal Performance | Temperature rise test | ΔT < 40°C at full load |

| EMI Compliance | EMI scanner measurement | Meets applicable standards |

Why Choose Olukey?

Partner with Olukey for your MOSFET driver circuit needs and benefit from:

- Expert technical consultation and design support

- Comprehensive product selection and availability

- Competitive pricing and flexible order quantities

- Rapid response and dedicated customer service

- Full warranty and after-sales support