Creating an H-bridge using MOSFETs is a fundamental skill in electronics, especially for motor control applications. As a leading MOSFET supplier and authorized semiconductor distributor, we’ll walk you through the process of building an efficient H-bridge circuit using quality components.

What Makes MOSFET H-Bridges Special?

H-bridges are essential circuits that enable bidirectional control of DC motors. While there are various ways to construct an H-bridge, MOSFETs offer several advantages:

H-bridges are essential circuits that enable bidirectional control of DC motors. While there are various ways to construct an H-bridge, MOSFETs offer several advantages:

- Higher efficiency with lower heat generation

- Fast switching capabilities

- Minimal voltage drop across the switches

- Suitable for high-current applications

Required Components

| Component | Quantity | Specifications |

|---|---|---|

| N-channel MOSFETs | 4 | WSF3036(A) or similar 30V/36A |

| Gate Drivers | 2 | Dual channel, bootstrap capable |

| Bypass Capacitors | 4 | 100nF ceramic |

| Bootstrap Capacitors | 2 | 100nF/50V |

Need high-quality MOSFETs for your H-bridge project?

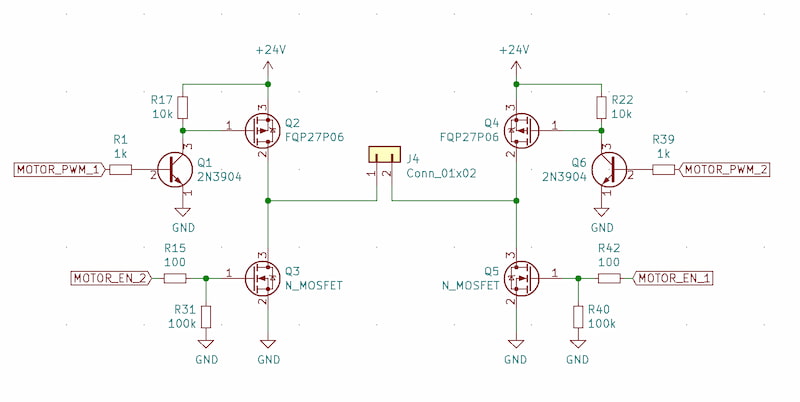

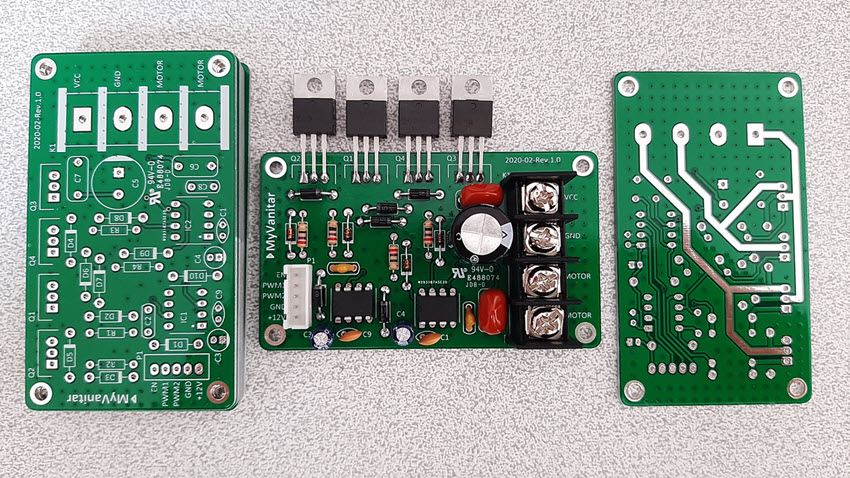

Step-by-Step H-Bridge Construction

1. Circuit Layout Planning

The H-bridge layout is crucial for optimal performance. Position the MOSFETs in an H configuration with:

The H-bridge layout is crucial for optimal performance. Position the MOSFETs in an H configuration with:

- High-side MOSFETs (Q1 & Q3) at the top

- Low-side MOSFETs (Q2 & Q4) at the bottom

- Motor connections between the pairs

- Keep gate driver traces short to minimize inductance

2. MOSFET Selection Guidelines

When selecting MOSFETs for your H-bridge, consider these crucial parameters:

VDS Rating:Should be at least 20% higher than your maximum supply voltage

Current Rating:Choose MOSFETs with ID rating 50% above your maximum motor current

RDS(on):Lower RDS(on) means better efficiency but higher cost

Gate Charge:Lower Qg enables faster switching frequencies

Recommended WINSOK MOSFETs for H-Bridge Applications

WSF3036(A)

- VDS: 30V

- ID: 36A

- RDS(on): 9.5mΩ

- Package: TO-252-2L

WSF40N06

- VDS: 60V

- ID: 50A

- RDS(on): 12mΩ

- Package: TO-252-2L

3. Gate Driver Implementation

Proper gate driving is essential for efficient MOSFET switching:

Key Considerations:

- Use dedicated gate driver ICs for reliable switching

- Implement bootstrap circuits for high-side MOSFETs

- Add gate resistors (10-100Ω) to control switching speed

- Include pull-down resistors (10kΩ) on gate inputs

4. Protection Mechanisms

Overcurrent Protection

Implement current sensing with shunt resistors and comparators

Thermal Protection

Add thermal sensors near MOSFETs

Dead-time Control

Ensure adequate dead-time (typically 1-2μs) between switching transitions

Flyback Diodes

Use fast recovery diodes or rely on MOSFET body diodes with proper rating

Common Issues and Solutions

Overheating MOSFETs

Causes:

- Insufficient heat sinking

- High switching losses

- Poor PCB thermal design

Solutions:

- Add proper heatsinks

- Optimize switching frequency

- Improve PCB thermal vias

Shoot-through Current

Causes:

- Insufficient dead-time

- Poor gate driver timing

- EMI issues

Solutions:

- Increase dead-time

- Improve layout

- Add snubber circuits

Need Professional Assistance?

As an authorized MOSFET distributor, Olukey provides:

As an authorized MOSFET distributor, Olukey provides:

- Technical consultation for your H-bridge design

- High-quality WINSOK MOSFETs with guaranteed specifications

- Sample availability for testing and validation

- Volume pricing for production quantities